Electric vehicle fires are less likely, but they can happen in more dangerous places like garages.

The media war against electric vehicles goes through phases, with different attack strategies coming to the fore and others receding. But one fear that continually enflames enragement is the possibility of EV battery fires. Despite the statistics showing that these are far less likely to happen than with cars powered by fossil fuel, they do tend to last longer and are harder for firemen to extinguish. But 24M Technologies reckons it can significantly reduce the incidence of EV battery fires. I talked to the company’s CEO Naoki Ota and President Ulrik Grape about how their technologies could improve battery safety, as well as delivering better performance and recyclability.

Battling EV Fire Disinformation With 24M Technologies

There is a lot of disinformation about EV battery fires, or at least misleading framing. One British publication noted that in the UK electric car fires had grown from 131 in 2022 to 232 in 2024 – a rise of 77%. However, the number of EVs on British roads had risen from 664,148 in 2022 to 1.3 million in 2024 – a 96% increase. So overall EVs have become safer. There were 18,313 fossil fuel vehicle fires in the UK in the UK in 2024, 79x more than EVs fires, but there were only 26x more fossil fuel cars, so combustion cars were nearly three times as likely to catch fire.

Nevertheless, any vehicle fires are problematic. Just one incident can endanger life and necessitate an expensive manufacturer recall even if nobody got hurt. “EVs are safe, but there are incidents happening, and as you get more and more vehicles on the road, there’s going to be more and more fires,” says Grape. “In today’s social media, it’s going to get escalated. EV fires are much less frequent than combustion engine vehicle fires, but they are more volatile. They also tend to happen when you’re charging the vehicle, so then you have a risk to garages and being close to your home.”

Dendrite formation is the big danger for battery fires as cells age

This is where the design of the cell becomes important. “The more cycles a battery has, the more dendrites grow, and the more likely it is to be dangerous,” says Ota. This is like combustion engines, which are also more likely to catch fire when older. “EVs have been around less time, with even the oldest just ten years old. But people drive cars for 15 or 20 years. Also, as you put more energy density in a battery, it becomes more dangerous.”

However, more manufacturers are switching from Nickel Manganese Cobalt (NMC) battery chemistry to Lithium Iron Phosphate (LFP), which is already safer due to lower susceptibility to thermal runaway. BYD, for example, exclusively uses this technology. However, the safety still decreases as energy density increases, and the roadmap is steep particularly from Chinese companies. The classic demonstration of LFP battery safety involves driving a nail through a pack, which can cause immediate conflagration with NMC batteries, but this is less likely with LFP. However, 24M doesn’t see this as a realistic scenario. “This doesn’t represent a real internal short circuit,” says Ota. “An internal short circuit is a very narrow area than a thick nail, producing a much higher temperature.”

Enter Impervio: 24M Technologies’ Battery Safety Superhero

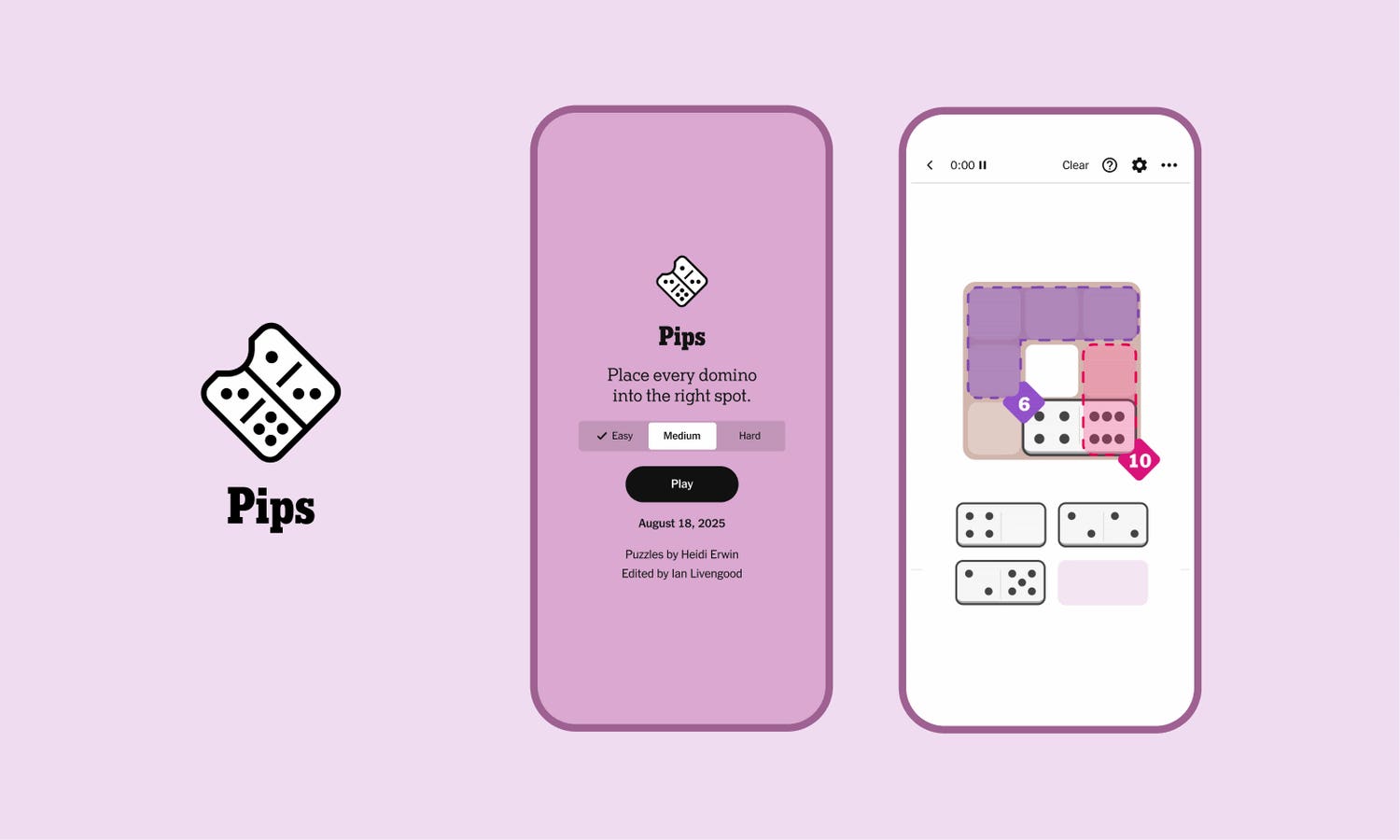

The technology 24M offers to combat this is called Impervio. “Impervio is a three-layer separator,” says Ota. The separator is the membrane between the anode and cathode, which allows lithium ions to pass through but prevents a short circuit. The short circuit problem comes when dendrites form from the anode side. If they reach the cathode, they cause an internal short circuit that can lead to a battery fire. Impervio’s third layer actively blocks dendrite formation and detects potential short circuits so they can be dealt with before they become dangerous, via cell replacement. “When a dendrite reaches the impervious layer, it doesn’t grow vertically from anode to cathode. It grows horizontally and in the end is dissolved, so it never gets to the cathode. This doesn’t add a lot of cost. We can utilize the existing separator. It’s like ceramic coating.”

The extra middle layer of Impervio prevents dendrites growing from the anode to the cathode

Just a few car fires can cause a company to recall all potentially affected vehicles, costing billions, because they can’t detect which cars will fail. Ota likens Impervio to an airbag – you might never have to use it, but it’s worth having just in case. “When an internal short circuit happens, it goes in milliseconds,” says Grape. “Once it starts, you can’t stop it from the outside. The only other method being tried is containment, packaging something around the cell. The uniqueness of the Impervio separator is that it can tell you this cell has to be shut down because it’s approaching a dangerous level. Back in the 60s, the seatbelt was introduced that made car passengers safe. Then we added the airbag to make them even safer. That is the message with Impervio. We’re getting to such a high energy density in the cells that there are risks of contaminations. Impervio provides protection that allows you to do more targeted recalls versus all the cars of a particular model.”

Portfolio Of 24M Technologies For Batteries

In 2010, 24M Technologies was spun off from MIT by its founder, professor Yet-Min Chang. The lithium-ion flow battery was his original technology. Kyocera has been a strategic investment partner for five years, helping this to develop into a SemiSolid battery cell. Since then, Volkswagen took a 25% stake in 24M Technologies in 2022, leading to the development of more new technologies such as Impervio, addressing areas of energy density, low temperature performance, rapid charging, recyclability and safety.

One technology is called ETOP, standing for Electrode to Pack. This bypasses the traditional cell-to-module-to-pack assembly. Instead, the pack is built from the electrodes directly. This provides a significant increase in energy density and goes further than the cell-to-pack systems being developed by Tesla, BYD and CATL. “We’re taking it one step further by making a unit cell, which is basically two or three electrodes, so the anode and the cathode are packaged in a unique way, and then we can build the pack from there,” says Grape. “We eliminate the module stage.” This increases packaging efficiency from 60% to 70-80%. “You can either pack more energy into the same volume or make a smaller pack that contains the same driving range.”

Eternalyte makes lithium ion flow 4x faster at -10C

Another 24M technology is called Eternalyte, which is a new electrolyte that improves battery performance. Using Eternalyte, Lithium ions in a battery can move twice as fast at room temperature and four times as fast at -10C, dramatically improving battery charging times and enabling six-minute recharging from zero to 80%. “Zero to 60% would probably take two to three minutes,” says Ota. “If the car can drive 600 kilometers, within two minutes you can add 360 kilometers, so it’s very close to gasoline.” Eternalyte also remains liquid at -40C, unlike traditional electrolytes, so poor cold weather EV performance and range would be a thing of the past too.

Lithium Forever is a little different. This is about the end of life for batteries and their recycling, particularly LFP, which can be so cheap to manufacture that recycling them isn’t cost effective. “Traditional recycling takes the old battery and melts it or uses chemicals to create a big ‘black mass’”, says Ota. “Then they try to extract expensive metal only. Iron is a cheap material, and they don’t want to even extract aluminum.” This is why LFP batteries are less likely to be recycled.

Many batteries are too cheap to manufacture for recycling to be cost effective

“They only recycle 10 to 20% at the moment,” says Grape. “That’s why we need to think of avoiding the black mass process.” Batteries must be designed with recycling in mind so their component elements can be separated again. No polymer binder is used with Lithium Forever, enabling over 90% of materials, including active substances from the anode and cathode, to be recovered without the costly and energy-intensive black mass process. This makes LFP economically viable to recycle, too, and the materials recovered pure enough for reuse in new batteries. The process can reduce active material recovery costs from $20-30 per kg to $2-3. “Now we can recycle very pure copper and aluminum,” adds Ota.

The 24M Technologies SemiSolid batteries are already being manufactured by Kyocera, currently aimed at its Enerezza residential storage system. Kyocera has also commercialized Lithium Forever. There are 24M partnerships in China and India. Some big names that Ota and Grape couldn’t mention are testing Impervio and Eternalyte. The 24M Technologies’ systems have potential to improve the experience of battery electric vehicle ownership in many areas, but Impervio is the one that is likely to help combat public perception of BEVs and the ongoing misinformation. “LG and Samsung had big recalls,” says Ota. “If they used Impervio, they wouldn’t have had to recall because they could just replace the failed cell. They could save lots of money.” If battery fires almost never happened, this would also mean one less argument for the anti-BEV media war.