Generic drugs account for more than 90 percent of prescriptions filled in the United States. Recent … More

America’s generic drug supply, most of which is manufactured overseas, is not consistently safe. Currently, the website of the U.S. Food and Drug Administration’s Office of Generic Drugs tells a different story.

“The Office of Generic Drugs (OGD) ensures high-quality, affordable generic drugs are available to the American public. Generic drugs account for more than 90 percent of prescriptions filled in the United States. FDA-approved generic drugs have the same high quality, strength, purity and stability as brand-name drugs. The generic manufacturing, packaging, and testing sites used must pass the same quality standards as those of brand-name drugs.”

The second of these statements is true. The other three are not. Generic drugs account for the vast majority of prescriptions filled in the U.S. However, the FDA’s assertions that all generic drugs are of equal quality are contradicted by investigative reports, drug testing and the agency data. It can, and must, do better.

Recent Generic Drug Enforcement Actions

Here are a few recent recalls, taken from the FDA’s website:

- Black hair found in a tablet of levothyroxine, a thyroid medication: 1.3 million tablets recalled

- Three fused tablets of metformin, a diabetes medication, were found in a bottle of gabapentin, a medicine for seizures or nerve damage: 11,000 bottles recalled

- Black spots indicative of microbial contamination were found on tablets of an antibiotic sulfamethoxazole and trimethoprim: 6,396 bottles recalled

- Levofloxacin tablets (an oral antibiotic) had the wrong identity number imprinted on the tablets: 10,052 bottles recalled

- Samples of cephalexin, an antibiotic, failed impurity/degradation tests: 59,556 bottles recalled

Although the FDA can request or mandate a recall, most are initiated voluntarily by the manufacturer. Despite these efforts, understrength or contaminated products enter the United States every day because our nation does not test generic drugs to independently confirm their quality and safety before providing them to patients. In light of the FDA’s blanket assurance, U.S. drug importers and the pharmacies and healthcare systems they supply see no need to do so.

Inspecting Manufacturing Plants Is Not Enough

The FDA has long relied on plant inspections to keep our generic drugs safe. This worked reasonably well when the bulk of drug manufacture was U.S.-based. However, as globalization shifted most production offshore, the agency struggled with a growing backlog of inspections. The pandemic made things worse. Then, the agency lost 20% of its personnel to HHS-mandated budget cuts.

Last month, ProPublica published a stunning investigative report. It revealed that “The FDA has given more than 20 foreign factories a special pass to continue sending drugs to the U.S. even though they were made at plants that the agency had banned.”

According to ProPublica, the FDA “has relentlessly pressed to keep the supply of low-cost generics flowing even as its own inspectors warned that some of those drugs posed a potentially lethal threat to the American public…Even when the agency did investigate and single out factories that were among the worst in India, it still gave them access to American consumers.”

The Food And Drug Administration is responsible for ensuring the quality and safety of generic … More

Why Is FDA More Worried About Preventing Drug Shortages Than Assuring Safety?

In 2008, the deaths of more than 200 Americans were linked to defective batches of heparin made in China. In response, newly appointed FDA Commissioner Margaret Hamburg cracked down on overseas drugmakers. When this resulted in severe shortages of more than 200 medications, including drugs used to treat cancer and deliver emergency care, Congress howled. This prompted the FDA to quietly prioritize minimizing shortages over assuring safety.

Some in the agency objected but were quickly overruled. Others were kept in the dark, as was Congress and the American public. “We felt we didn’t have to make it a public thing,” said Dr. Janet Woodcock, who spent more than half of her four-decade FDA career directing the agency’s Center for Drug Evaluation and Research, which oversees approval of new and generic drugs. Reportedly, she feared disclosure would trigger “some kind of frenzy” among consumers. “All the while,” ProPublica noted, “patients took their medicine without question, trusting an agency that has long been considered the gold standard in drug regulation.”

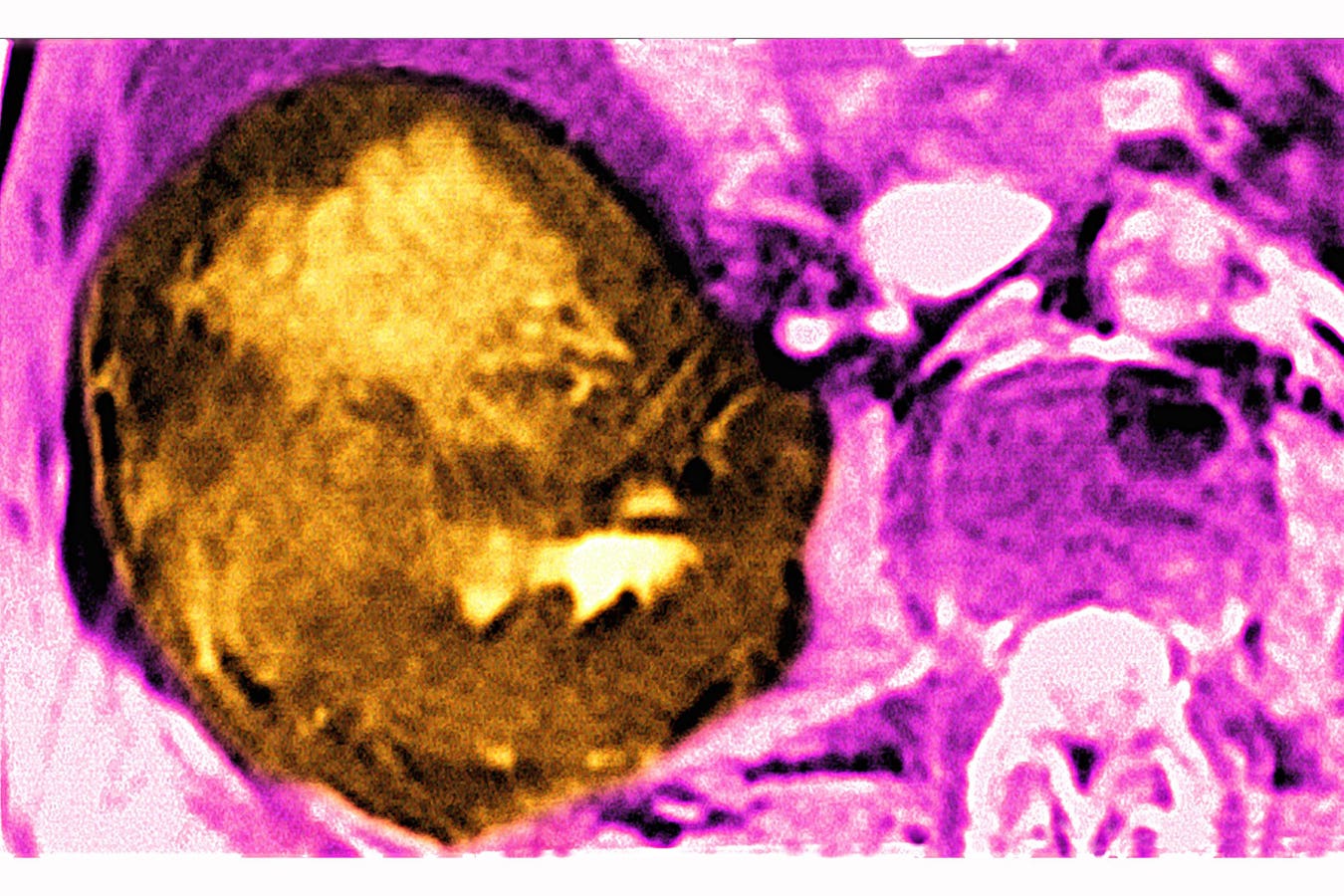

Importing Substandard Generic Drugs Has Consequences

In a related report, ProPublica profiled Joe DeMayo, who lost the kidney his wife had donated to him despite faithfully taking his transplant medications. He was unaware at the time that an anti-rejection drug he was taking, tacrolimus, was produced by an Indian manufacturer with a lengthy record of FDA safety violations. Since then, a preliminary analysis of selected drugs purchased by the U.S. Department of Defense has revealed alarming variability in the quality of tacrolimus, as well as other essential generic drugs offered to the DoD by vendors.

The number of patients harmed by defective generic drugs is difficult to quantify, but potentially large. Rosemary Gibson, author of China Rx, says that “FDA has lost control over the quality of generics. In my view, we are importing unregulated medicines. If we don’t reverse this downward spiral, our drug supply will look like that of a developing country.”

The FDA And Administration Can Solve This Problem

Instead of perpetuating the problem, the FDA should solve it. Here’s how the agency and the administration could improve generic drug safety and reduce future shortages:

- Openly acknowledge the variable quality of our generic drugs. Although many generic versions meet standards, a concerning minority do not. Instead of assuring the public that all FDA-approved generic drugs are equally safe, the agency should acknowledge that this is no longer the case.

- Endorse product testing by certified, independent labs. When doctors and patients realize that the quality of their generic drugs cannot be longer be taken for granted, they’ll want products that have been independently tested to verify their safety. The FDA should encourage U.S. drug importers and the large health systems and pharmacies they supply to periodically test samples of imported drugs produced by different companies to identify conscientious manufacturers. If tainted or under-strength drugs are found, the findings should be forwarded to the FDA for further investigation and possible regulatory action.

- Improve FDA monitoring of adverse events. This would enable the agency to cross-walk worrisome patient reports with product test results to track the scope and scale of the generic drug quality problem.

- Instruct federal agencies to choose drug suppliers based on “best value” rather than best price. In most cases, high-quality generics are only slightly more expensive than substandard products. Aligning the market to value will enable conscientious U.S. and overseas manufacturers to compete and win.

- Rebuild America’s capacity to produce high-quality generic drugs. Advanced pharmaceutical manufacturing, an approach pioneered in Virginia, can make high-quality medicines and ingredients at lower cost than traditional methods. Rebuilding resilient and reliable supply chains for essential drugs is in our national interest.

FDA Commissioner Makary did not cause the generic drug problem, but he can fix it. If these strategies are adopted, our nation’s patients will benefit, we’ll have fewer drug shortages, be less vulnerable to a sudden embargo, and enjoy a stronger economy.

My views are my own, and do not neccessarily reflect those of any current or past employer