A new fire research facility on the outskirts of Wellington New Zealand puts flooring and cladding materials to the ultimate test.

Burn tests allow scientist understand how building materials and structures perform in real-world fires

Image credit: Building Research Association of New Zealand

Just before 1 am on 14 June 2017, a fire broke out in Grenfell Tower, a high-rise apartment block in West London. Triggered by an electrical fault in a fridge-freezer, the fire should have been a minor one; quickly containable and easily extinguished by the London Fire Brigade.

But unbeknownst to the residents and the firefighters, there was a problem with the tower’s exterior cladding. Added during refurbishments a year earlier, the cladding was made from aluminum panels filled with highly-flammable polyethylene, and backed with combustible insulation. Once the fire “breached the window of Flat 16”, it rapidly spread through the cladding, eventually engulfing the entire building with flames.

The Grenfell Tower disaster became Britain’s worst residential fire since the Second World War, causing the deaths of 72 people and injuring hundreds of others. The inquiry concluded that the fire “was the culmination of decades of failure”. It led to changes in the way firefighters are trained, investigations into contractors and materials providers, and ongoing reforms to building safety regulations.

TOPSHOT – Police man a security cordon as a huge fire engulfs the Grenfell Tower early June 14, 2017 in west London. The massive fire ripped through the 27-storey apartment block, trapping residents inside as 200 firefighters battled the blaze. (Photo by DANIEL LEAL/AFP via Getty Images)

AFP via Getty Images

Testing exterior cladding

“The world woke up with Grenfell”, says Peter Whiting, Fire Testing Team Leader at BRANZ, the Building Research Association of New Zealand. “What that incident showed us is that it’s not just a single component that leads to the spread of fire, it’s how one material might influence another material and so on. The whole building assembly is important.”

I’m visiting Whiting at the brand-new fire laboratory at BRANZ, 25 km from Wellington. The lab is huge and open, with a footprint of about five NBA basketball courts. I’ve also been assured that five double-decker buses parked on top of one another still wouldn’t touch the roof.

“This facility has been a decade in the planning,” says Whiting. “Our previous fire lab is 50 years old and seriously space-constrained. What we have now is incredible.” Every aspect of this new building has been designed to allow it to safely test the fire performance of materials used in the construction and marine industries. The team splits their time between fundamental research and commercial testing of real products.

In front of us, as we discuss Grenfell, stands a pair of multi-story steel frames. They’re L-shaped and mirror one another, so that one resembles an interior corner, and the other an exterior corner. “These are facade testing rigs,” explains Whiting. “So, what we’d do is build the facade here on the frame, using the product we’re testing, and put instruments such as temperature sensors, onto it. Then, we stack about 400 kg [~882 lbs] of timber sticks on top of one another in this square box at the bottom, and ignite it.” This is a ‘reaction to fire’ test – it allows researchers to study exactly what happens to a facade material in the presence of fire; measuring how far the fire spreads, and how quickly.

Pointing to the interior corner frame, Whiting continues, “It will look like essentially like an apartment gone to flashover, with flames escaping out the window impacting on the facade. And because of that return wall, there’s an entrainment of the fire. It acts almost like a chimney, in a way, with the shape encouraging the burn.”

From outside, the complex exhaust and scrubber system of the fire lab can be seen. The original research facility was housed in the two grey buildings to the left of the new one.

Image credit: Building Research Association of New Zealand

Nearby is an area where larger prefabricated structures can be tested – even entire buildings up to three-stories tall. “The output of the fire in the facade rig is around 3.5 MW,” says Whiting. “Here, we can reach 10 MW.” During open burn tests, a large exhaust hood is lowered down over the set-up to capture the noxious emissions. Outside the lab is a series of enormous steel vessels and a complex network of pipes. These, Whiting tells me, are mostly part of the wet scrubber system. The polluted gas produced by the fire and captured by the hood gets pumped through the scrubber, which is a series of solvent sprays that capture specific pollutants for storage. The only emission that reaches the air is steam.

Fire resistance

Along one side of the vast room sit three boxy furnaces of different sizes; 3 – 6 m [10-20 ft] wide, 3 – 4 m tall, 3 – 5 m deep. These form the basis of the lab’s ‘resistance to fire’ testing. “Here, we want to know how well an element resists the passage of fire from one side to the other,” Whiting explains. “So, say your neighbor’s property or the next hotel room to you is on fire. How effective is that separation at keeping you safe?”

To determine this, they use a technique called oxygen consumption calorimetry, which is based on the fact that the amount of heat released by a fire is directly proportional to the amount of oxygen consumed. The measurement involves setting up a burner in the furnace, close to the material-under-test, which might something like a room lining. By carefully monitoring the concentration of oxygen in the exhaust gases, and the gas flow rate, the scientists can calculate a heat release rate for that material, which defines its fire resistance performance.

Test materials can be mounted onto the walls or the roof of each furnace – whatever best reflects its use in real buildings. They can also test beams, air conditioning ducts, pipes and cables. Whatever they’re testing gets lifted into place using a 40-tonne crane that spans the building, high above the lab floor. The same crane also maneuvers materials and structures to and from the open burn area. “It’s absolutely the most used bit of kit in the whole facility,” laughs Whiting.

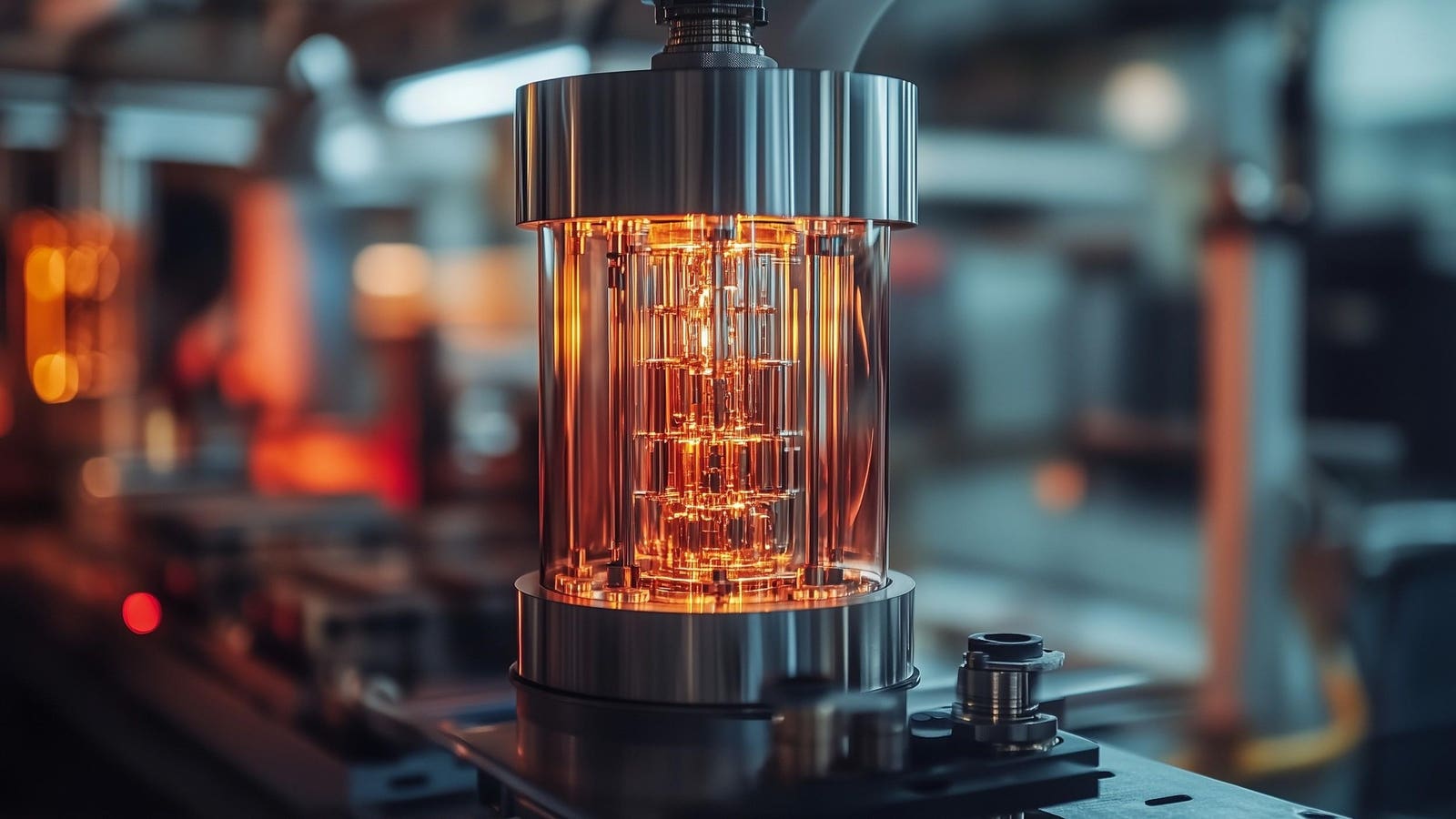

Combusted LPG is used to generate high temperatures and fires within the lab’s furnaces.

Image credit: the author

One of the reasons the lab has three sizes of furnace, he explains, is because “the bigger we can test something, the more accurate we can be in extrapolating those results,” to understand how it’d perform a multi-story structure. They can also measure fire performance at the other end of the scale too. In a room within the original fire lab, I saw their cone calorimeter – effectively a mini version of what’s used in the furnaces, but more accurate for small samples. It will soon move into the new facility.

In the days surrounding my visit, Whiting and team had been working to commission and calibrate the furnaces, and I was lucky enough to witness a test of a burner system. Inside the open furnace, a ‘fake’ wall made from refractory (fireproof) concrete had been installed. “We don’t need to heat the whole chamber for this,” he says. From the control room, engineers switched on the burners, and six flames shot out from the furnace walls first yellow, then blue in color – combusted LPG (propane), reaching a temperature of 1,980°C [3596 °F]. Whiting had warned me that it would be loud, but even on a low setting, it sounded like a jet engine. I’ll admit, I was entranced. “This sorta thing is why you end up spending your entire career working here,” he says.

New Zealand’s climate is predicted to get hotter and drier in the coming decades. That combined with a slow-but-steady shift to denser housing is likely to lead to an increased fire risk in cities. Understanding how building materials and systems perform in real-world fire scenarios has never been more important.