Invisible ‘in‑between’ links still sabotage modern tech. Specialist chipmakers are now racing to secure signals and restore reliability

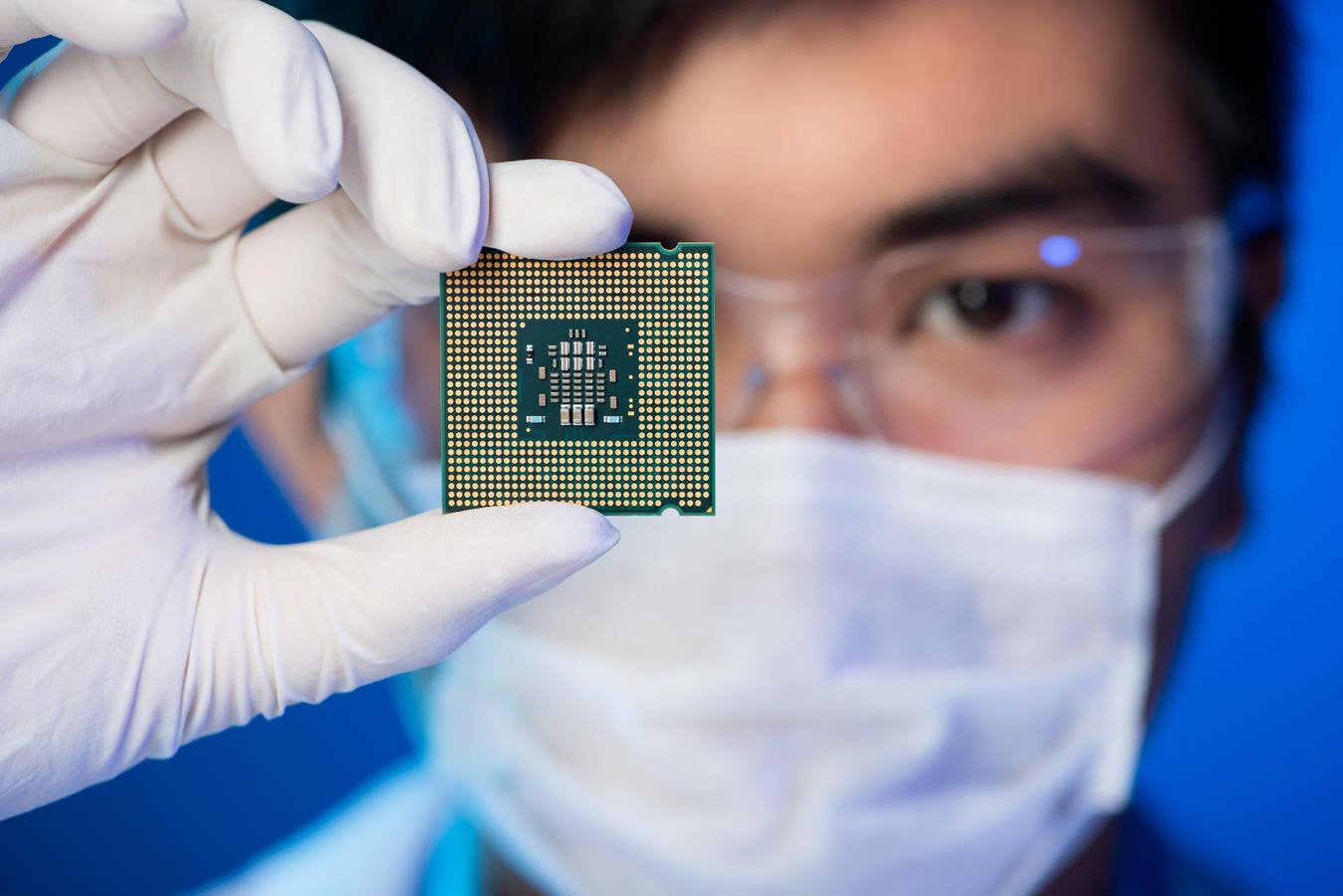

Every modern action, from tapping a phone to steering a car, relies on semiconductor muscle. Yet our video calls still freeze, medical images blur, driver‑assist alerts misfire, and everyday functions fail far too often. What consistently breaks is not the headline compute, it is the fragile ‘in‑between’ layer that ferries raw signals from sensor to processor and from board to board.

It is the fragile ‘in‑between’ layer that ferries raw signals from sensor to processor and from … More

“It’s often not your internet, it could be your USB cable maxing out its bandwidth, or a flaky connector dropping frames before they even hit your screen,” says Valens Semiconductor CEO Gideon Ben Zvi. “While we keep blaming ‘the network,’ the real fault often lies a few centimeters of copper away.”

Industry‑wide, only a minority of the roughly 600 U.S. chip firms keep dedicated signal‑integrity teams; most chase clock speeds and process nodes instead, and that leaves huge swaths of functionality exposed.

Valens Semiconductor, public on the NYSE since a $1.1 billion SPAC merger in 2021, focuses specifically on these ‘in‑between’ layers, building chips that keep video, control, data, and power signals clean and synchronized over interference‑prone cables in cars, medical devices, industrial vision, and pro‑AV. “The ‘in‑between’ fragility ripples through critical domains. In a U.S. hospital network, intermittent, low‑resolution endoscope feeds were undermining confidence in minimally invasive procedures until the system migrated to a disposable‑scope architecture built on hardened long‑reach link,” says Ben Zvi. “Moving to a disposable‑endoscope architecture with our chipsets, would eliminate feed errors 98% of the time, giving doctors the real-time clarity they need to save lives.” The same approach shows up elsewhere; for video calls, they collapse camera video, audio, control, USB (and often power) into a single long‑reach, interference‑robust cable so the 4K image actually arrives intact. In vehicles they move multi‑sensor ADAS data over resilient links that shrug off EMI bursts before those errors can silently erode perception.

“solving the problems that show up in real‑world systems.”

Valens isn’t alone. More suppliers are targeting the ‘in‑between’ layer. Texas Instruments‘ active EMI filter ICs inject counter‑phase currents to reduce conducted and common‑mode noise, helping designers shrink traditional filtering components. Samtec‘s Flyover® twinax assemblies lift high‑speed lanes off lossy PCB traces to extend reach while maintaining signal margin. Spectra7 integrates analog equalization into ultra‑thin VR/AR cables so high‑resolution, low‑latency video can traverse lighter, more flexible tethers. Alphawave provides power‑efficient high‑speed SerDes IP tuned for longer, noisier channels, helping complex SoCs meet bit‑error and latency targets without excessive board complexity. Different markets, same takeaway.

As commodity performance plateaus in perceived user benefit, reliability and integrity in the ‘in‑between’ become sharper differentiators. “We’re not chasing headlines. We’re solving the problems that show up in real‑world systems,” Ben Zvi says, and that stance illustrates a broader strategic shift. Fixing the ‘in‑between’ won’t make benchmark splash, but it is what keeps surgeries sharp, cars safer, factories running, collaboration fluid, and without it, every layer of modern life remains vulnerable to silent, preventable failure.