Darth Vader’s eyes reflect no light

Getty Images

At a recent solar energy trade show, the first thing anyone would note is that solar cells are cheaper than ever before. Perhaps second, is that solar vendors had all sorts of solar panels. There were transparent and semi-transparent solar panels meant to act as windows on greenhouses and other buildings. Some solar panels were green, some sparkly, and even some pink solar panels. But, what color should solar cells actually be if we want to be the most efficient? The answer is black, because ideally you want all the sunlight that hits a cell to stay inside making electricity. If you see color that means some light escapes the cell and hits you in the eye. It is curious, however, most older solar cells and many still on the market today are blue single crystal or multicrystalline silicon rather than black. Why would solar cell companies let all that blue light escape?

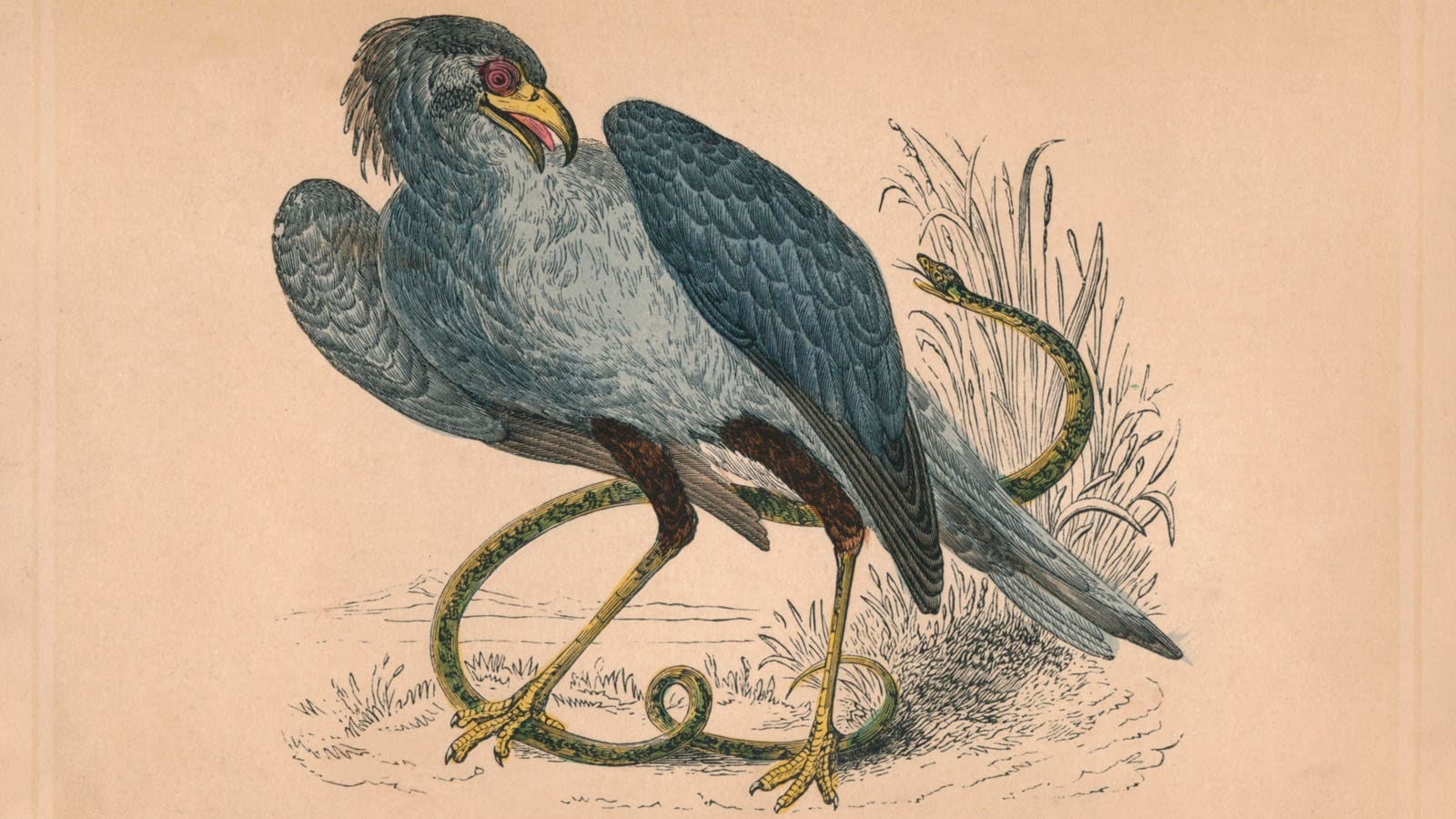

The Dark Side : Darth Vader’s Deathly Black Eyes

Researchers have known for several years that nano-texturing silicon makes black silicon, which is more efficient at capturing light than common blue-colored silicon solar cells. In fact, the record for a black silicon solar cell was set by a Finnish research team a few years ago. Black silicon literally has no color because the dry etching process takes a normally flat silicon surface and etches it into a forest of nanoscale needles. These needles grab the light and don’t let it get away. The reflectivity is less than 1%, which is a scientific way of saying it’s deathly black – like looking into the eyes of Darth Vader.

A high-resolution scanning electron microscope image of black silicon.

Chiara Modanese, Aalto University.

The reason that most solar cells are still blue is the process to make black silicon uses relatively expensive cryogenic reactive ion etching and demands relatively fancy atomic layer deposition to work. Industry consensus was these two techniques were too costly to implement in production. There are two bits of good news, which has set off an arms race that is seeing the entire industry shift to black silicon. First, it is possible to use inexpensive simple wet chemistry to get black silicon. For example, many groups and companies have used metal assisted chemical etching of silicon. In addition, a study I helped coauthor, found even with the expensive process the costs per unit power for black silicon solar cells dropped more than 10%.

Black silicon solar cell.

Ville Vähänissi, Aalto University.

Solar Arms Race

Industry was not totally wrong, we did find that black silicon processed cells were a whopping 15.8 -25.1% more expensive than making conventional cells, so it is easy to see why production engineers would immediately dismiss the idea. Not-so-obviously efficiency gains and the ability to go to the less-expensive multicrystalline silicon starting material using diamond-wire sawing far outweighed those extra costs: overall the cost per unit power dropped by 10.8%.

This is a big deal because all of the economics of solar photovoltaic systems hinge on the cost of the cell per watt. The 10% cost drop will also ignite another wave of increased solar deployment as lower cost cells per watt have a cascading effect on solar systems costs. If you have more efficient cells you need less land or roof area, less racking, less labor to install them and so on. International Energy Agency has already shown that now for several years solar power is the cheapest source of electricity in history. The prices just keep dropping and now we know that floor on costs can come down at least another 10%. For both businesses and families this means they stand to make a substantial rate of return going solar. In fact, solar is so cheap now it can even subsidize your heating costs.

Although processing costs for black silicon are more expensive the end results are less costly even in the worst case scenario.

The results of the study indicate massive photovoltaic market share will go to the first companies to get truly black silicon solar cells to market. The U.S. is already in a solar related trade war with China and Europe (and even Canada) with the goal to bring the rapidly expanding multi-billion dollar solar manufacturing business back to the U.S. Tariffs have had only a small impact so far, but black silicon is set to ignite an arms race between China, Europe and the U.S. as they each try to push truly black silicon throughout the solar market. For consumers this means lower priced solar electricity. It perhpaps turns out that Darth Vader could be a fan of power from the sun. Perhaps just like in the Star Wars movies something good will come from the dark side of solar.

MELBOURNE, AUSTRALIA – MAY 04: A Suns fan with a Darth Vader mask celebrates the win (Photo by Michael Dodge/Getty Images)

Getty Images